PrecisioNext Launches New Generation Fluxless TCB Equipment, Leading the Development of CPO Packaging Technology

PrecisioNext Launches New Generation Fluxless TCB Equipment, Leading the Development of CPO Packaging Technology

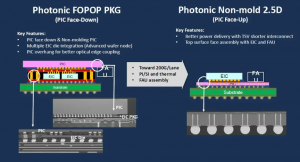

NEW YORK, NEW YORK, UNITED STATES, October 8, 2025 /EINPresswire.com/ -- PrecisioNext has officially released its new-generation Fluxless TCB equipment, Loong Advance. This equipment adopts a formic acid reduction system and offers a placement accuracy of up to ±0.5μm. It will be widely applied in future advanced packaging processes such as CPO, 2.5D, 3D, and Cu-Cu bonding.As a revolutionary optoelectronic integration technology, CPO integrates traditionally separated optical components, including electronic integrated circuits (EIC) and photonic integrated circuits (PIC), onto the same packaging substrate or interposer to form an optical engine (OE), which is placed around the ASIC chip on the substrate. Compared to traditional pluggable optical modules, CPO reduces power consumption by 50%, lowers latency to within 1 nanosecond, improves signal integrity by 18dB (63 times), supports ultra-high bandwidth beyond 1.6T, and offers higher integration density. These advantages are driving transformative waves in high-speed data centers, AI computing clusters, and communication networks.

According to authoritative forecasts, the global CPO market is expected to grow from $46 million in 2024 to $8.1 billion by 2030, with a compound annual growth rate (CAGR) of 137%.

In the current early development stage, CPO faces bottlenecks such as thermal management (3D stacking temperature >85°C), packaging yield (<85%), and high costs. CPO modules cost thousands of dollars, with packaging manufacturing accounting for 30%-50%+ of the total cost. Scaling production is necessary to reduce costs, and this proportion is expected to decrease significantly as the technology matures and mass production is achieved.

In CPO packaging manufacturing, the integration of EIC and PIC is one of the most critical steps. NVIDIA’s Spectrum-X Photonics CPO switch uses TSMC’s COUPE technology (a 3D packaging technology based on hybrid bonding). Intel’s Optical Compute Interconnect (OCI) CPO employs a silicon interposer + TCB (thermocompression bonding) for optoelectronic integration. Broadcom’s BCM78909 CPO, manufactured by TSMC, also uses TCB (a 2.5D packaging technology based on a silicon interposer).

TCB is currently the most mature and cost-effective solution for CPO packaging. Fluxless TCB eliminates the risk of flux contamination that traditional TCB may cause to optical chips, making it a core equipment for future CPO mass production.

Core Challenges of CPO Mass Production

Despite its significant advantages in performance and cost, the industry still faces several challenges in mass production:

1. Complex Packaging Process: CPO systems require highly complex advanced packaging technologies such as thermocompression bonding (TCB) or hybrid bonding, as well as precise optical coupling integration, stringent testing processes, and yield management to ensure system reliability.

2. Silicon Compatibility: There are doubts about whether silicon-based photonic integrated circuits (PICs), especially photodiodes (PDs), can achieve sufficient performance breakthroughs to compete with traditional optical modules using indium phosphide (InP) photodiodes.

3. Durability and Thermal Management: Since all optical components are tightly packaged within the switch ASIC/xPU system, they must withstand high temperatures and maintain stable performance, posing extreme demands on durability and thermal management.

4. Reliability Issues: The optical engine (OE) is tightly integrated with the ASIC on the same PCB/substrate (and potentially even on the interposer in the future). This means that if a single optical engine fails during production or operation, the entire package (including the high-cost switch or xPU chip) may be scrapped. Therefore, pre-packaging testing of the optical engine is crucial, directly impacting product yield and reliability.

Why TCB Process Is the Preferred Choice?

The TCB process, with its three major advantages—precise temperature control, sub-micron accuracy, and controllable stress—has become the preferred feasible solution for heterogeneous integration of EIC and PIC, perfectly addressing the challenges of complex packaging processes:

1. Low-Temperature Bonding (Addressing Thermal Damage): The bond head precisely controls the temperature at 150~200°C (far below the 250°C+ of reflow soldering), locally heating only the bumps to avoid overall substrate heating and protect heat-sensitive optical components.

2. Sub-Micron Placement Accuracy (Key to Optical Coupling): Real-time optical alignment + closed-loop control dynamically adjusts the placement head position to compensate for thermal drift, achieving ultra-high precision optical alignment (sub-micron level), which is critical for efficient optical coupling in CPO.

3. Fluxless Process (Avoiding Optical Contamination): The fluxless process avoids optical contamination, maintaining extremely high cleanliness of optical interfaces.

4. Stress Management (Addressing CTE Mismatch): Precise force control applies 5~50N of flexible pressure to avoid brittle PIC cracking; bump material innovations, such as low-modulus solder (e.g., In/Sn alloy) or copper hybrid bonding, absorb stress.

5. High-Density Interconnects: Supports micro-bump pitches as low as 10μm, enabling a large number of electrical signal connections (high I/O count) between electrical chips and silicon photonic chips.

6. Excellent Material Compatibility: CPO packaging involves various materials (silicon, III-V compound semiconductors, glass, organic substrates, metals, etc.), and the interconnect process must be compatible with these materials.

PrecisioNext—China’s Leader in TCB Equipment

PrecisioNext’s Loong series TCB thermocompression bonding machines break international monopolies. The newly launched Fluxless TCB equipment, Loong Advance, is suitable for TCB processes such as CPO, HBM, CoWoS, and oDSP, providing customers with full closed-loop support from R&D to prototyping and mass production. To date, PrecisioNext has completed TCB prototyping for over 10 customers, involving 2.5D, 3D, CPO, and other fields. It is the only domestic manufacturer capable of providing process development, prototyping, and equipment. PrecisioNext’s DA403 COB/COC ultra-high precision die bonder is already being supplied in large quantities to the world’s largest optical module manufacturer. The Fluxless TCB equipment, Loong Advance, will help domestic CPO manufacturers achieve scaled mass production, cost reduction, and efficiency improvement. As CPO advances into the 3.2T+ era, TCB will further integrate technologies such as laser heating and copper direct bonding (Cu-Cu Direct Bonding). As a key technology for next-generation CPO, it will support the continuation of the "Moore’s Law" for optoelectronic chips.

Jack Li

Dongguan Precision Intelligent Technology Co., LTD

+86-13825438413

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.